|

ECO iso System |

NATURAL SOUNDPROOFING &

NATURAL ABSORPTION |

| NATURE AND TECHNOLOGY TOGETHER FOR AN IDEAL SOLUTION |

|

|

|

|

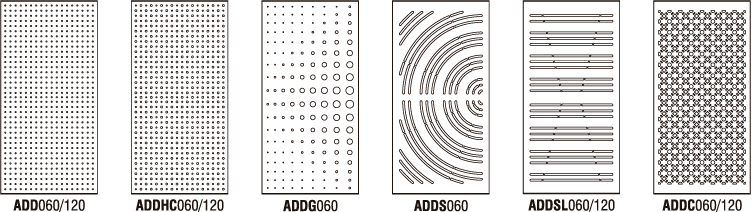

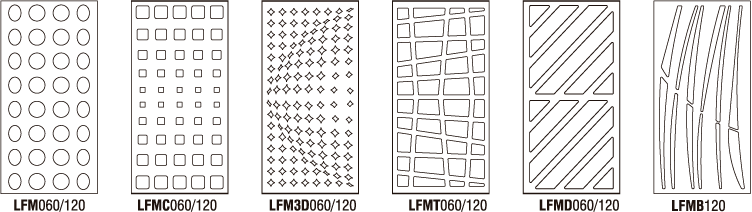

Following an ecological philosophy, JOCAVI® has designed this

line of acoustic insulation and treatment materials, which are made

exclusively from natural raw-materials, like cork and coconut. This

line of products provides a practical and efficient solution for

acoustic insulation and treatment, with the associated benefit of the

thermal component. It is composed of expanded cork agglomerate

(as an acoustic and anti-vibration insulation material), coconut fibre

(as an acoustic energy absorbent material), and perforated panels

made of coloured pressed wood fibre that gives it an attractive

finishing. This compound, made of strictly 100% natural ecological

materials, has an excellent technical performance. The unique

features of these raw materials combined in the ECOiso provide it

with a high degree of thermal, acoustic and anti-vibration insulation

and airborne noise reduction. This product represents the most

practical, efficient and ecological solution to build high-quality

acoustic insulation and treatment. The ECOiso is ideal to install in

music and television studios, business spaces, auditoriums,

conference rooms, restaurants and bars, etc..

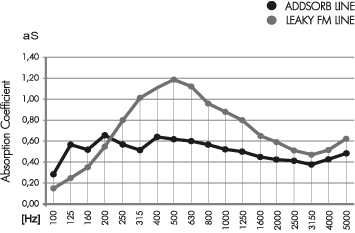

The coconut fibre is a natural, renewable and very light vegetal

material. It has high porosity (95% of pores), which translates into

an extremely high absorption of sound energy.

The exceptionally good behaviour of the expanded cork

agglomerate, in terms of Insulation and dimensional elasticity,

associated with the coconut fibre's micro-porous absorbent

properties, are the natural binomial for first-class acoustic solutions.

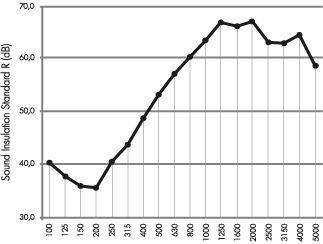

Therefore, outstanding performances and a significant reduction of

sound levels by means of structure-borne and airborne transmission

are guaranteed. The high level of performance that is obtained

from this combination of coconut fibre and expanded cork

agglomerate is hard to obtain from other materials.

The acoustic behaviour of the ECO iso®(cork + coconut + wood)

delivers a natural combination, and ensures solutions with superb

acoustic performances to reduce sound levels, as well as an excellent aesthetical and decorative integration.

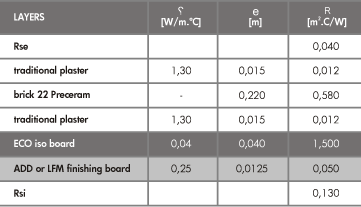

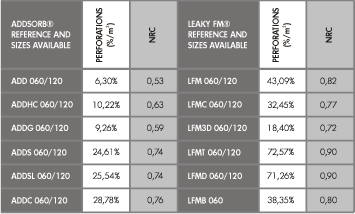

COMPOSITION

The ECOiso system is composed of two types of elements in plates

and some accessories. The first element to be applied is the Acoustic

Insulation, and the second element is the Acoustic Absorber that

gives the final decorative finishing. Accessories are: wooden slats,

wall plugs, bolts and glue. |